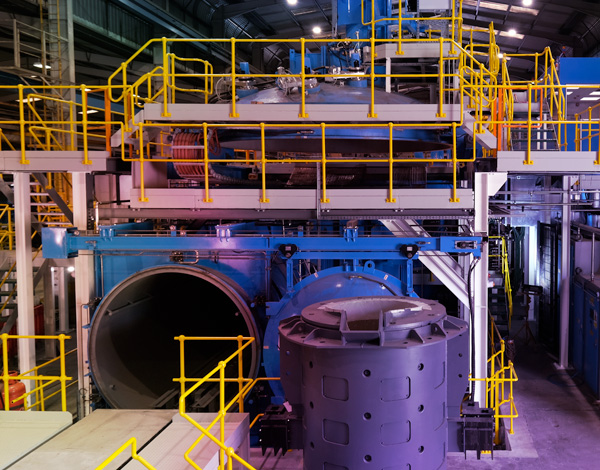

Vacuum induction and air induction melting

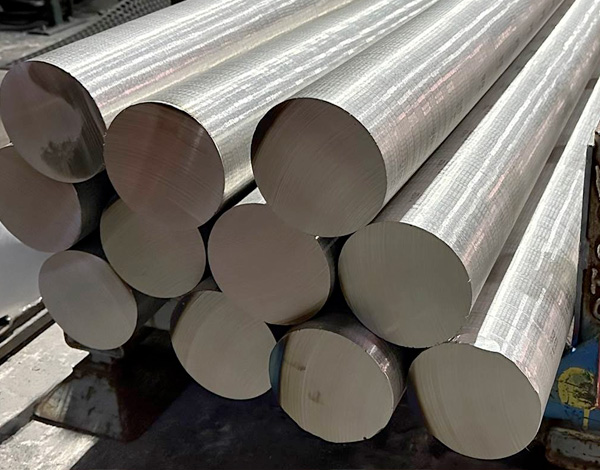

Technical excellence in the production of superalloys for critical-use applications.

Whether it’s small or large volume production, all nickel, cobalt, and iron base alloys are produced by either vacuum induction or air induction melting to the industry’s most stringent specifications.

Leading manufacturers of critical products rely on the commitment to "pure performance" for quality and on-time delivery.